Bio-degradable Hydrogel

A new hydrogel of interest for regenerative agriculture

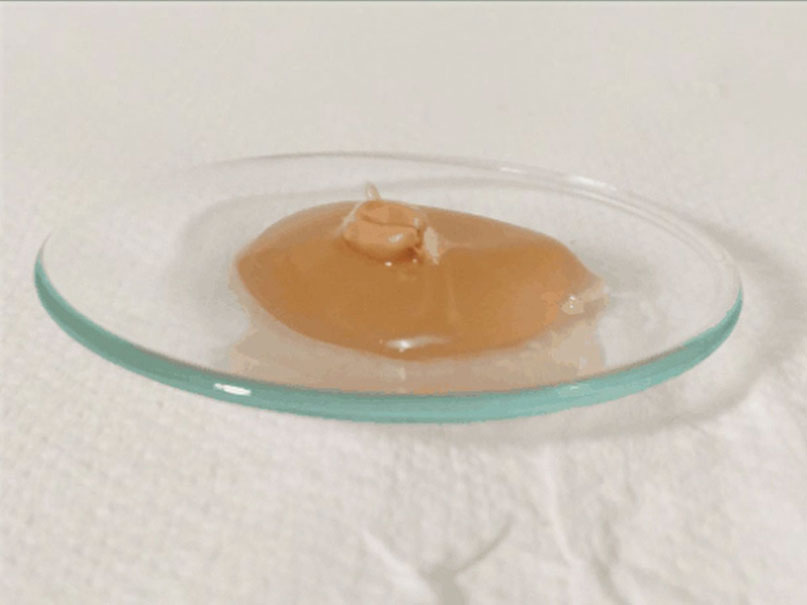

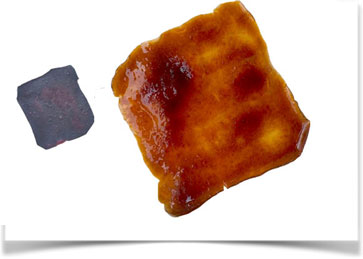

In the dry state it shows a very rigid consistency, it can usually be added to the soil as a granular product, in the presence of water it is able to hydrate over 200 times its dry weight (low conductivity water). The degree of swelling can be changed as desired

Sustainability

The hydrogel is entirely made of products of natural origin and able to positively interact with the biosphere and soil.

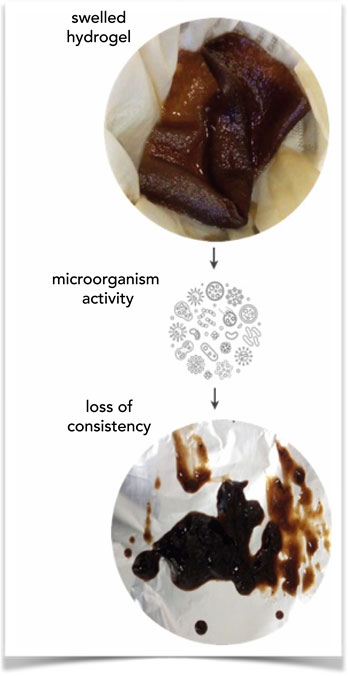

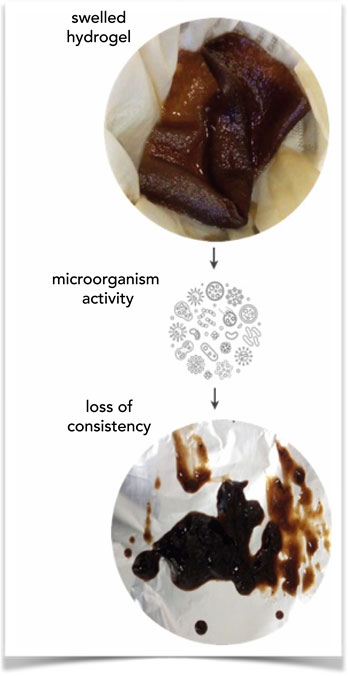

Degradation process

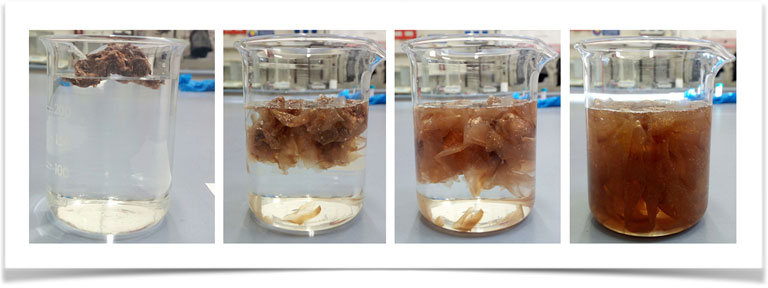

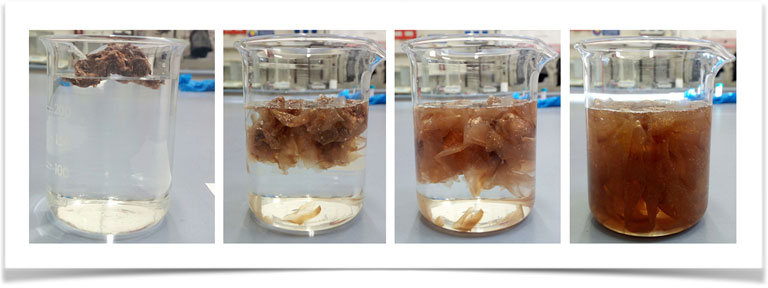

When immersed in the ground, the swollen hydrogel undergoes a degradation process that can be described in three phases:

Step 1) The network breaks and the structure collapses, the hydrogel loses its consistency but can still hold water.

Phase 2) The dissolved polymer is absorbed by the soil,

Phase 3) The polymer degrades completely over a period of time that depends on several factors: microbial activity, temperature, type of soil, climate.

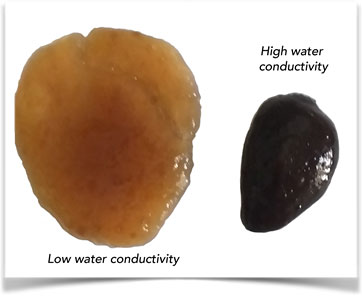

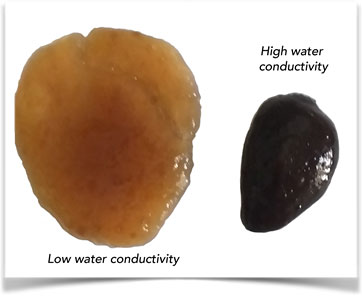

Conductivity influence

The degree of swelling of the hydrogel is influenced by the conductivity of the water: the higher the water conductivity, the lower the degree of swelling. It is possible to calibrate the swelling degree to counteract high water conductivity.

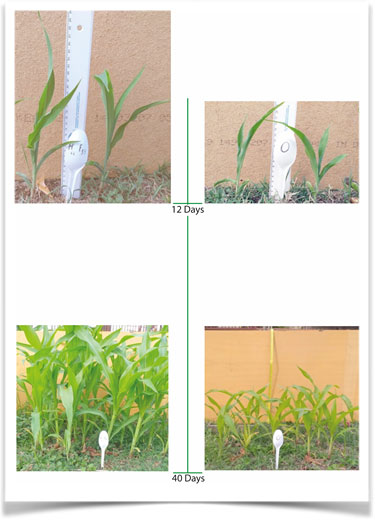

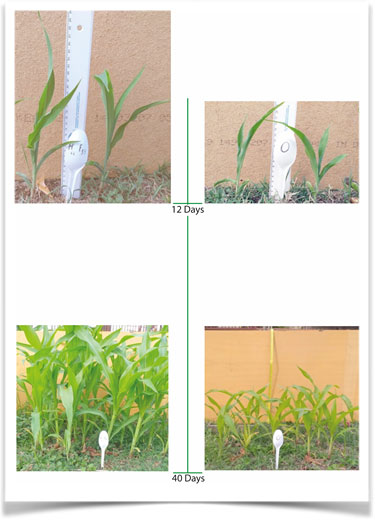

It support growth of plants

Tests have been conducted proving that hydrogel influences positively on plants growth. Small quantities of hydrogel were put in the soil (or media), the hydrogel absorbed water and influence the crops during a limitate time lapse of 20-30 days. Plants treated with hydrogel show a greater growth. The hydrogel acts first as a water retainer, then as soil conditioner nutritive for microorganisms and plants.

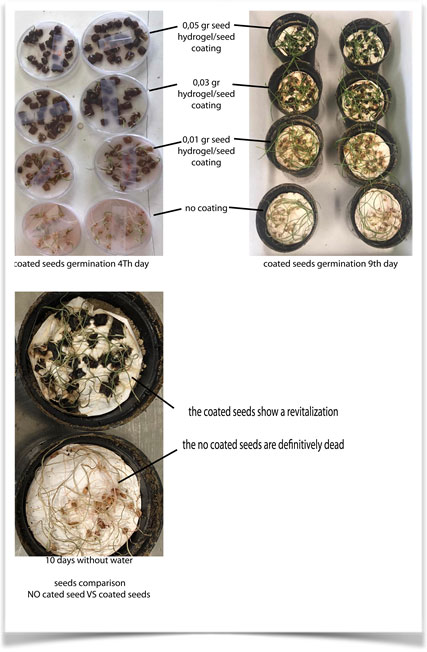

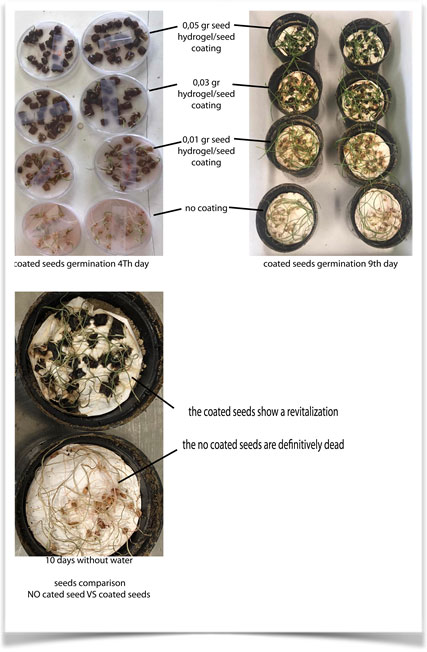

Hydrogel against seeds dehydratations

Seeds coated with a tiny layer of dried hydrogel, after first hydration, can withstand water scarcity longer than seeds unsupported by hydrogel.

The hydrogel acts as a water storage and slow water releaser as well.

Sorption effect

The Hydrogel is an organo-mineral compound, it shows an affinity for positively charged ions and different species of molecules. Its composition can be modified in order to favor the absorption of some substances and act effectively as a slow releaser.

Green synthesis

The synthesis does not require high energy inputs, nor raw materials dangerous for the environment; it does not create hazardous waste for humans or the environment.

The product can be synthesized with a technology already identified in collaboration with a company in northern Italy.

Degree of technological readiness

The product was tested in the laboratory, in an assisted climate environment and the first open air tests were conducted. Trials are underway to evaluate commercial applications. TRL 4-5